- precision is blowing in the wind

How to get energy from the wind ?

Wind is a movement of air, it is created by atmospheric changes, such as temperature or pressure, and also under the influence of the shape of the terrain. Wind turbines are devices that generate electricity. They are divided into two types: with a vertical axis and with a horizontal axis of rotation. Regardless of that, each wind turbine consists of: a tower, nacelle with generator and rotor with blades.

During the production of towers and wind blades, it is important to maintain the imposed tolerances and precision of workmanship to ensure the designed aerodynamics and durability. It is determined by the forces and loads to which the structures of wind towers are subjected. To support production and installation processes related to wind energy, we offer you:

- measurements of production forms

- measurements and acceptance of nacelle components

- control of components and assembly devices

- commissioning of elements of tubular towers

- alignment of tower segments

- geometric control of foundations and connections on offshore farms

- measurement of the flatness of foundations and the position of assembly bolts

- support with the assembly of laminate molds (cores)

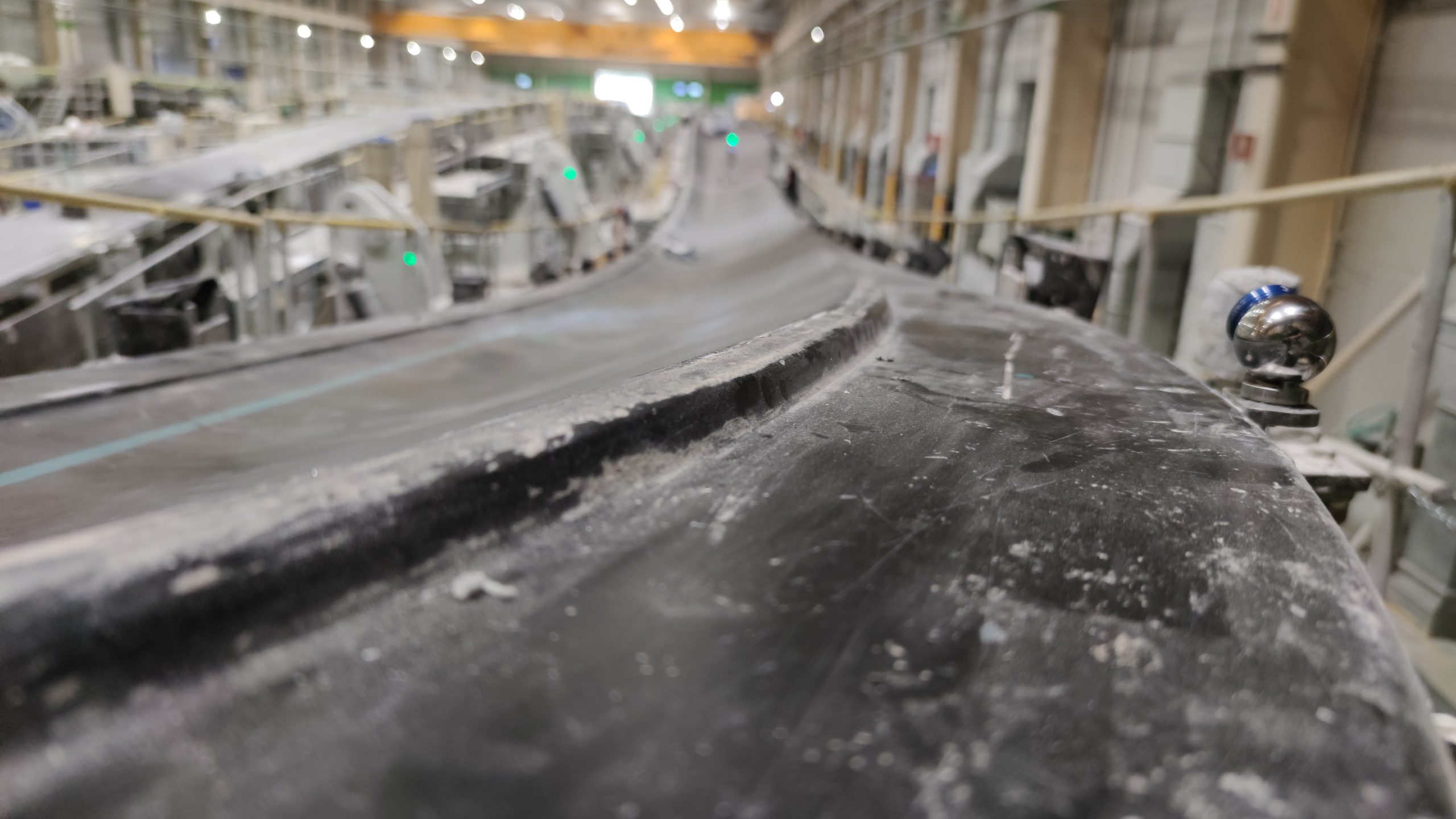

- blade acceptance measurement

Mainly 3 construction structures are used for the construction of towers: steel, concrete and lattice. It is also common to use a combination of these methods.

Steel towers:

They are usually made of segments prepared from bent and welded sheets of metal. The segments are placed on top of each other and butt-welded. When positioning segments, remember to keep all parts of the structure aligned.

Concrete towers:

This type is rarely used, it is constructed in two ways – made on the construction site or from prefabricated elements, assembled on the construction site. The first type is mainly used in hybrid solutions. However, the use of prefabricated elements allows the construction of high towers with high stiffness.

Lattice towers:

They have many advantages, which include the lightness of the components (steel profiles), ease of transport and assembly. The lower self weight of the tower enables the use of smaller foundations, which results in lower investment costs.

Wind farms are also located offshore. The basis of their construction are foundations, which, due to their structure, are distinguished by:

- monopile

- tripile

- jacket

- tripod

- floating foundation

We check the geometry of foundation connections both on off-shore and on-shore farms.

Offer

Our offer for the wind energy industry includes:

- Setting the correct dimensions during blade mold reconstruction,

- Acquisition of 2D/3D digital data for the reconstruction of damaged parts,

- Periodic dimensional and geometry checks of blade molds,

- Supervision and quality control, including analysis of defects in wind turbine components,

- Technical expertise and geometric control of wind turbine blades and production molds,

- Inventory and visualization of industrial facilities – for planning the modernization of factories producing large-size elements for wind farms

- Virtual assemblies – quality control before and after assembly of elements,

- Checking the geometry of wind turbine elements

About us

P3D – blow out the uncertainty

Our engineers have gained experience during many measurement projects related to the production of wind turbine elements and their components. We offer you reliable measurement services to ensure the highest quality production and stable operation of wind turbines.

office@p3d-metrology.com

+48 787 747 888

www.p3d-metrology.com

Benefits

Thanks to our services, we can provide:

- lower renovation costs of the blade molds,

- Shorter downtime during modifying the length of the molds,

- ensuring the correct quality of manufactured components,

- avoiding assembly mistakes and unexpected costs,

- efficient and fast assembly processes,

- easier planning during designing and building of new production halls