- Accuracy and precision, ensuring the correct operation of production lines

During the production of household appliances, it is necessary to properly take care of the plant’s machinery park due to the benefits that can be obtained by ensuring the proper functioning of production lines. The constantly growing requirements and the demand for household appliances force plants to increase the pace of production while ensuring high quality of the product and aesthetic value. When intensifying the operation of production lines, it is necessary to control the condition of the working machines, their mutual positioning, preservation of mutual geometrical relationships and wear of consumable parts. Precise industrial measurements are very helpful in the implementation of such tasks.

What are the challenges facing the household appliances manufacturing sector?

The changing needs of the household appliances market determine the necessity to introduce technological innovations. Nowadays, consumers also attach importance to the aesthetics of household goods, which is why manufacturers have to perform detailed quality controls of molds and their shape.

What is innovation in the household appliances sector?

It is very important for consumers to improve and modernize products. The modernization process may concern its entire structure or individual elements. Very useful in this aspect are computer tools and equipment that allows you to verify the correctness of the element by comparing it with the designed 3D model.

Innovation is also related to the introduction of new products to the market. In this case, firstly prototypes are made, before approval for serial production, they must pass many quality checks. Production lines should be adapted to new tasks, and new molds and control devices should be properly and precisely made.Our offer includes services supporting the prototyping process such as PPAP (Production Part Approval Process), reverse engineering, 3D scanning, surface modeling and many more.

Increasing the production capacity of a factory is often associated with an increase in machine operation. It usually means an increase in the transmission speed of semi-finished products, and acceleration of assembly and control processes.

Offer

Our offer for household appliance industry:

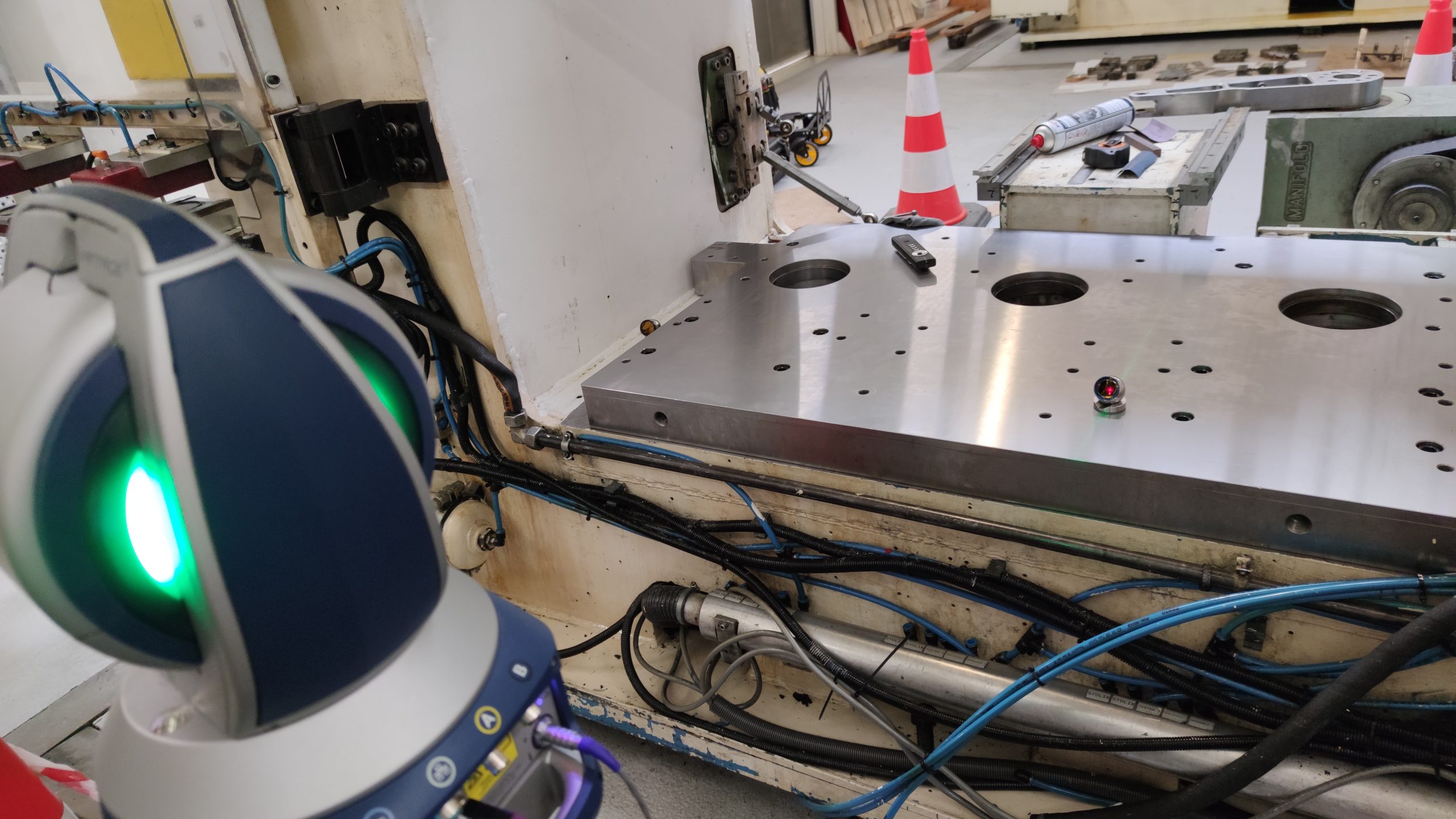

- Setting the geometry of machines and devices – production fixtures

- Acquisition of digital 2D/3D data – geometry reconstruction of used machine components when technical documentation is missing,

- Periodic inspections – checking the repeatability of production machines,

- Supervision and quality control – during production to maintain the required quality,

- Technical expertise – detection of assembly errors on production lines,

- Inventory and visualization of industrial facilities – for modernization planning,

- Support during relocation and assembly – leveling and setting up production lines,

- Checking machines geometry during downtime.

About us

P3D – ANALYSIS / GEOMETRY / DIAGNOSTICS

Our specialists have gained invaluable experience by carrying out numerous quality checks, modernization and expertise at plants producing household appliance machines and devices.

Using our experience and technological possibilities, we can offer services that increase efficiency, productivity and quality of production.

office@p3d-metrology.com

+48 787 747 888

www.p3d-metrology.com

Benefits

With our services we provide:

- improvement of the quality for better products,

- longer uninterrupted operation with good quality,

- increased level of reliability on production,

- increased production flow and efficiency,

- speed up of the production process,

- fast and accurate data for reverse engineering

- improved quality that lowers costs.

The biggest companies of household appliance sector:

- BSH

- Whirlpool

- ABB

- Amica

- Samsung