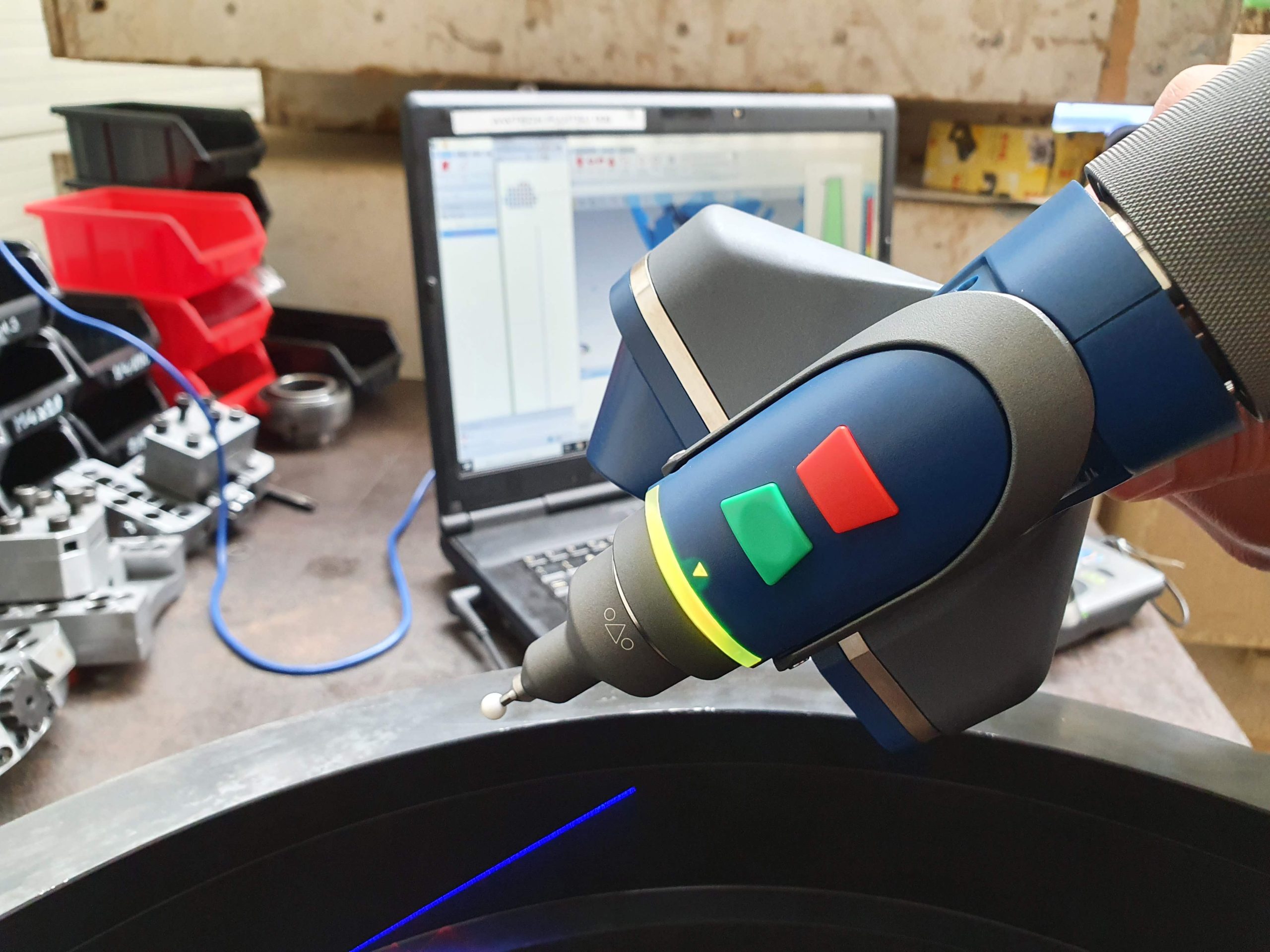

- High accuracy & precision maintained in the most difficult environment

Foundry is one of the oldest techniques of manufacturing metal elements where specific shape and properties are needed. Beginning of foundry starts at 7000 BC. Then civilizations were able to melt gold and cast metals.

In the past was mainly cast:

- jewelry

- metal reliefs

- statues

- everyday articles

- church bells and doors

- elements of pumps and water supply

Nowadays, modern foundry is associated with production for almost every industry. From the automotive to the medicine industry. The development in that field resulted in an increased investor’s requirements. They need really high quality products in short deadlines.

How metrology services can positively affect the forge and foundry industry?

The final product made by foundry plants must meet the design assumptions and specifications. In order to keep all the imposed tolerances, the producers of castings must pay attention to the condition and quality of:

- casting molds and dies

- machines for making foundry molds and cores

- automatic molding lines

- injection molding machines

- molding compound preparing machines

- wax models

To ensure the required quality of the final product, we recommend using our services before starting the production. By controlling the condition of equipment and tooling you can gain assurance of the quality of final products.

Offer

Our offer for foundry and forging industry includes:

- Setting the geometry of forging rolling mills and leveling big structures,

- Acquisition of 2D/3D digital data – reconstruction of damaged molds,

- Periodic dimensional and geometry checks of forging tooling & dies

- Supervision and quality control – prototype approval before production,

- Technical expertise – checking casting allowances vs 3D CAD model,

- Inventory and visualization of industrial facilities for renovation planning,

- Support in relocation and machines assembly process – leveling and settlement of foundations check,

- Checking the machine’s geometry during downtime – condition of hammers and presses.

Main companies of forge and foundry industry in Europe:

About us

P3D – Our services allow you to keep production processes in good shape

Thanks to our experience in solving complex measurement problems, our engineers are able to perform a wide range of works related to metrology in heavy industry. We are using the latest technologies and years of knowledge to meet the toughest challenges. We are experts in projects where accurate and reliable measurements are key to maintaining the continuity of the factory’s operation.

office@p3d-metrology.com

+48 787 747 888

www.p3d-metrology.com

Benefits

With our services we provide:

- improvement of the quality of end products,

- longer uninterrupted operation on production lines,

- better prevention of machine failures and avoiding downtime,

- extended service life of machines in the long period of time,

- increased production flow and efficiency,

- improve the production process to increase competitiveness,