- Our services satisfy the hunger for knowledge.

In the food industry, it is very important to use reliable machines working in long periods of time without sudden breakdowns. Food processing plants need to satisfy market needs on a daily basis. All of this causes enterprises of this type to need continuous development and modernization of existing machine parks.

Machine parks in the food industry are usually equipped with machines such as:

- industrial mixers

- dough sheeters

- industrial ovens

- injection molding machines

- welding machines

- mills

- industrial tanks

All of that machines should be:

- be precisely adjusted and leveled (it eliminates tension)

- their elements be perfectly aligned, parallel or perpendicular (it causes right wear of parts)

- their foundations ensure a solid and correct assembly (it assures working stability)

- be regularly inspected (it ensures operation flow)

- be subjected to an expert opinion after renovation / modernization (ensuring safety during operation)

- be carefully inspected after relocation (for warranty purposes)

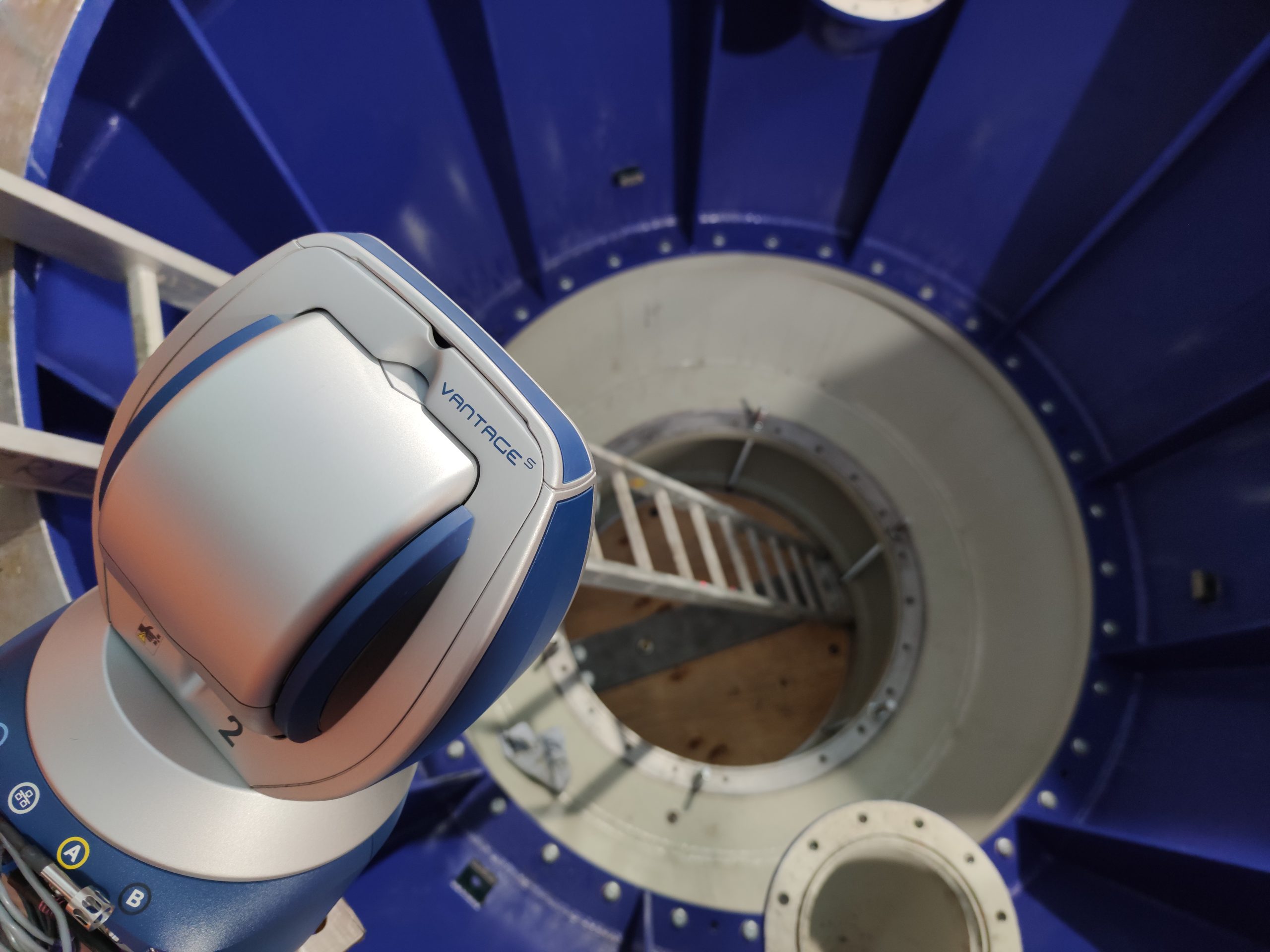

Our offer includes many measurement services that we can perform without contact, which helps to maintain sterility. We also have the option of making spatial scans in hard-to-reach and closed areas. Later on visualizing their condition through the real visualization of the conditions prevailing in them. We can even recreate them in virtual reality, to which we can “move” you straight from your desk.

The food industry is also associated with the pharmaceutical, chemical, tobacco and alcohol industries. Our team is also prepared to support these industries.

Offer

Our services for the food production industry:

- Setting the geometry of automatic systems and robotic stations,

- Acquisition of 2D/3D digital data – reconstruction of machine elements or calculation of the volume of tanks,

- Periodic dimensional checks – guidelines for setting up production lines,

- Supervision and quality control – checking the repeatability of machines,

- Technical expertise – detection of assembly errors in food production machines,

- Inventory and visualization of factories for expansion planning,

- Support for relocation and assembly – leveling foundation setting,

- Checking geometry during machine services – component wear control.

About us

P3D – hungry for precision

Due to our vast experience, we can offer you a number of measurement services necessary at various stages of factory life.

We support the processes of modernizing existing lines, optimizing production processes by controlling and improving the geometry of devices, as well as providing information for the reverse engineering of damaged machine parts.

office@p3d-metrology.com

+48 787 747 888

www.p3d-metrology.com

Benefits

Thanks to our services, we can provide:

- longer uninterrupted operation of production lines,

- increased production flow and efficiency,

- faster design of damaged machine parts,

- improved safety of the production process,

- speed up of the production process,

- fast and accurate data for reverse engineering