- We process raw data and extract precise information.

Material processing is closely related to extraction of raw materials. Machines operating in that industry have to withstand hard environmental conditions. That’s why keeping all machinery in good condition is crucial for downtime prevention.

Which machines are working in the processing and extraction industry?

- ore conveyors

- crushers

- tubular ball mills

- roller mills

- tube mills

- vibro sieve machines

- excavators and wheel loaders

- bucket wheel excavators

- drilling rigs

- transporting systems

Operating conditions for those machines can be destructive for their elements. Presence of high temperature, vibrations, huge loads, dust and sand is bad for bearings and precise elements. That’s why we should check the condition of those machines, this is the only way to prevent breakdowns and downtimes and also to keep workers’ safety on high level.

Processing of mineral resources

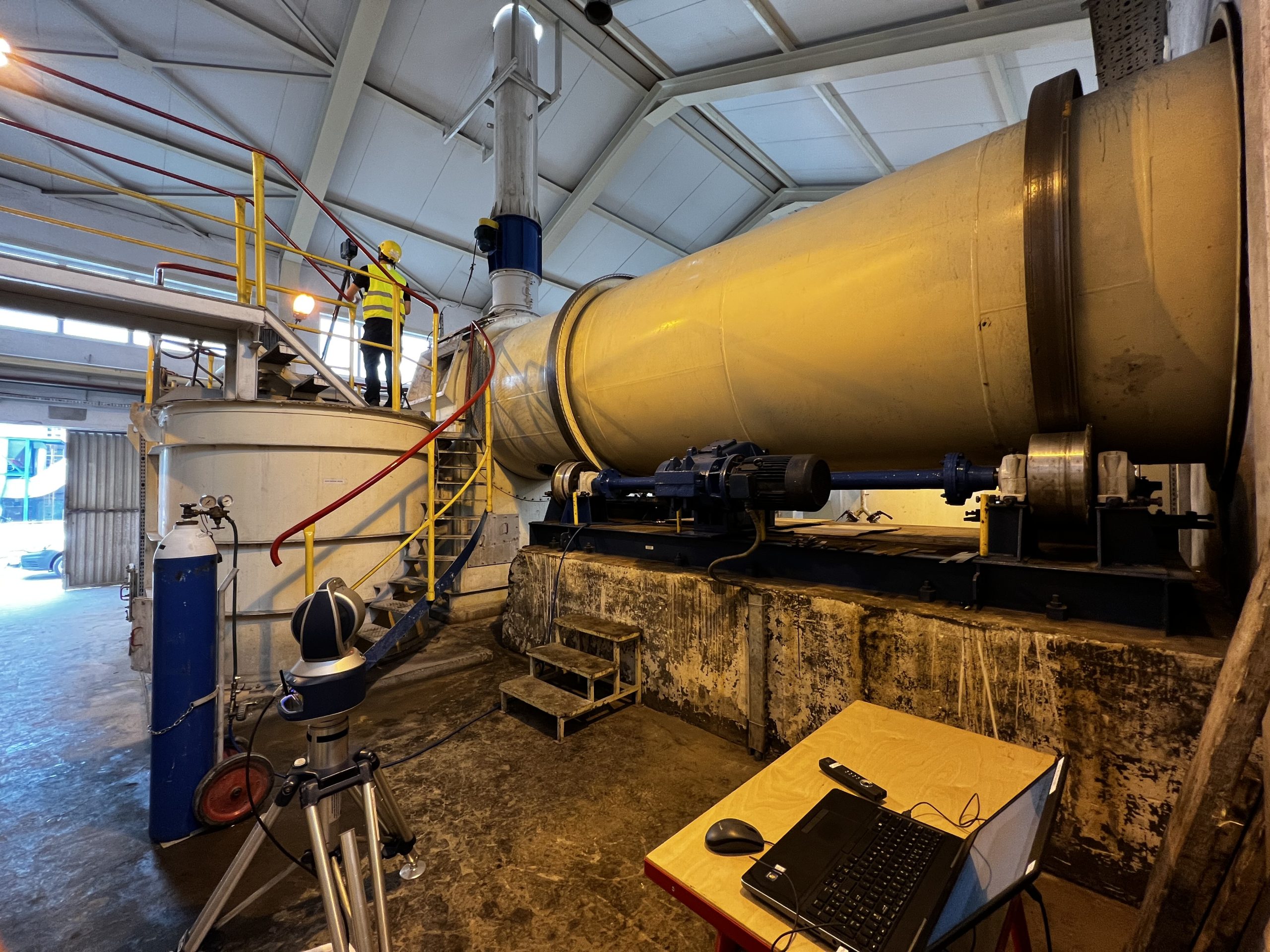

Before distribution of resources we need to extract and process them in a way that other industries will be able to make further processes. The cement, ceramics, mining and energy industries use tubular ball mills. They are used for grinding raw materials of medium and low hardness. Due to continuous rotation of the cylinder with low abrasion balls inside the inserted material is being grinded.

Paper factories

Paper factories are using timber as a raw material in a paper production process. Chemical processing is the first stage. The result of that is wood pulp. This is the main component of the paper.

In the preparation of the pulp, we can specify the following stages:

- Grinding the paper pulp with special knives that cut, grind and crush the pulp – this stage determines the final quality of the product.

- Next stage is based on adding glue to the pulp to obtain the required properties of the paper.

- Paper filling, pigments and additives are added to the paper pulp at this stage to impart color, softness and smoothness.

This is followed by dyeing, dilution and cleaning of the paper pulp. The mass prepared in this way is subjected to the fulling stage:

- Paper pulp dewatering through special screens.

- Rolling

- Squeezing out the water

The last process of paper production is the formation of the paper web, where it first goes to the presses again, where it loses the remaining amount of water. Then it goes to drying cylinders, which evaporate the rest of water and resin at a temperature of 120 ℃.

Offer

Our offer for raw materials processing and extraction industry includes:

- Setting the geometry of ball mills and leveling big structures,

- Acquiring digital 2D/3D data – volume and area calculations,

- Periodic dimensional and geometry checks of grinding rollers and tables,

- Quality control and supervision of subcontractors during machines services,

- Technical expertise – detection of assembly errors causing excessive vibration and damages,

- Inventory and visualization of industrial facilities – 3d scanning the interior of tanks to check the wear condition,

- Support in relocation and machines assembly process – setting and alignment of machines components,

- Checking the geometry during downtime – rollers and drive shafts alignment

About us

P3D – precision in raw data processing

Thanks to our experience in solving complex measurement problems, our engineers are able to perform a wide range of works related to metrology in heavy industry.

We are using the latest technologies and years of knowledge to meet the toughest challenges. We are experts in projects where accurate and reliable measurements are key to maintaining the continuity of the factory’s operation.

office@p3d-metrology.com

+48 787 747 888

www.p3d-metrology.com

Benefits

With our services we provide:

- reduction or elimination of vibrations,

- longer lifetime of machine components,

- better prevention of machine failures,,

- extended service life of machines,

- increased production flow and efficiency,

- improvement of the technological processes